In this guide, we will demonstrate how to remotely perform a 12-volt battery conversion on a new Porsche Cayenne using Launch SmartLink C.

The vehicle originally comes equipped with a 12-volt lithium battery, which is prone to damage. Repair costs for these lithium units are high, and a full replacement is even more expensive. Converting to a standard lead-acid battery presents a more economical solution.

In this case, the customer has already installed a new lead-acid battery and modified the wiring harness. However, dashboard warning lights persist, indicating that a system adaptation is required.

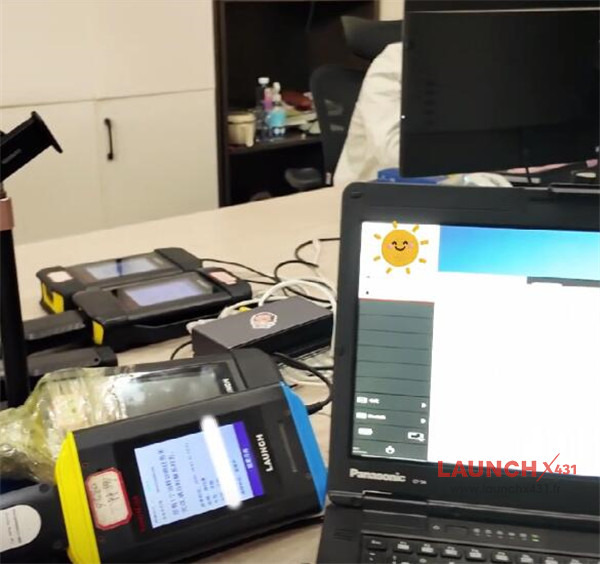

Here’s how the remote repair process works:

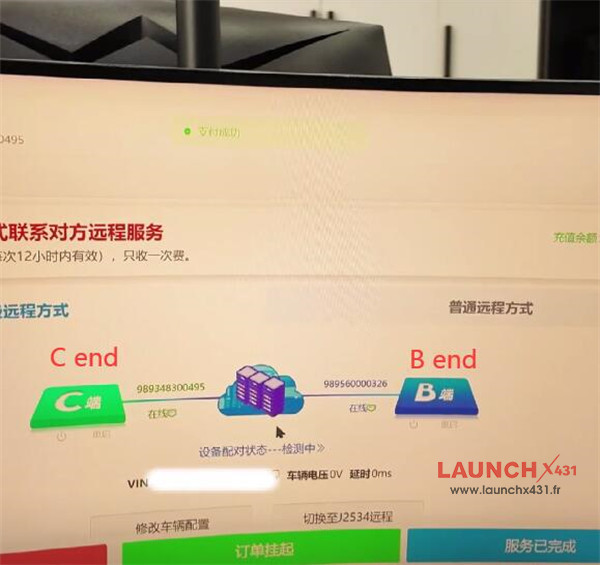

A repair shop (CN) posts a service request.

Our remote expert (BN) accepts the order and selects the relevant vehicle module.

The CN interface automatically switches to the connection screen.

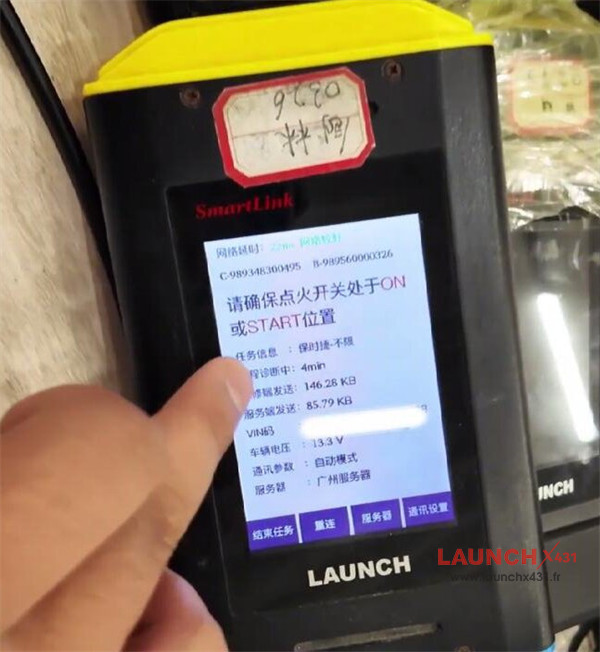

Once the connection between SmartLink C and SmartLink B are successfully established, our specialist uses advanced diagnostic software to access the vehicle’s systems and make the necessary configuration changes. This platform is incredibly convenient for workshops that may not have access to specialized tools.

The entire modification was completed in just four minutes of connection time.

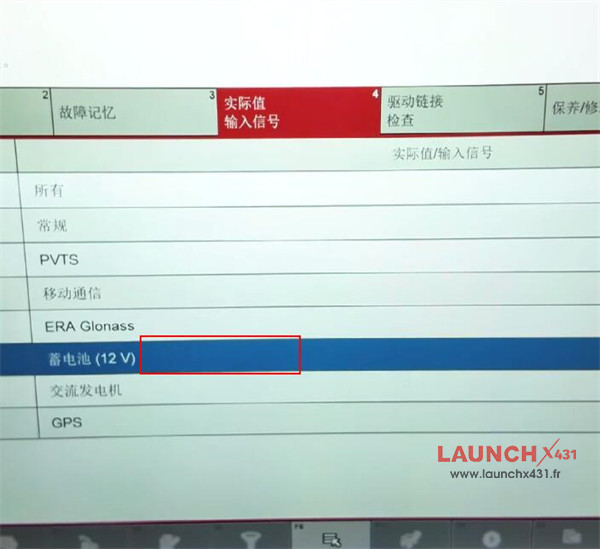

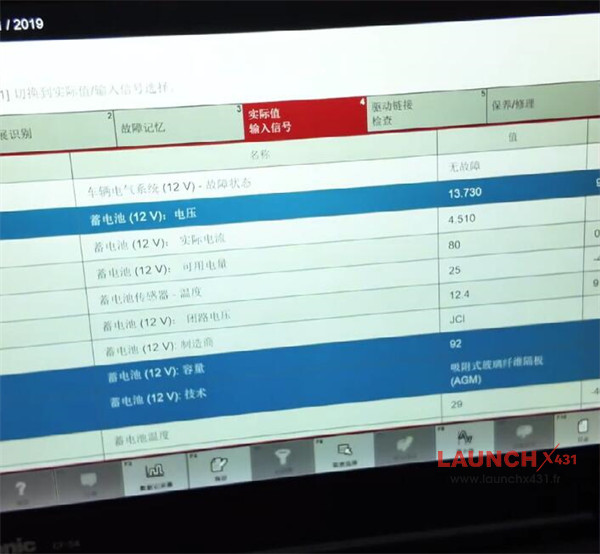

To confirm the success of the modification, we access the gateway module to read the data stream. By selecting the 12-volt battery data, we can see the battery voltage and a confirmed capacity of 92 Ah, which identifies it as an AGM start-stop battery. This verification confirms a successful conversion from a lithium to a lead-acid battery.

The modification results are normal: the dashboard warning lights have cleared, and the vehicle is ready for standard operation.

And just like that, the battery conversion is complete. This process breaks down geographical barriers. No matter the distance, and even without specialized diagnostic tools on site, any workshop with an internet connection can easily resolve complex issues.

Video guide: